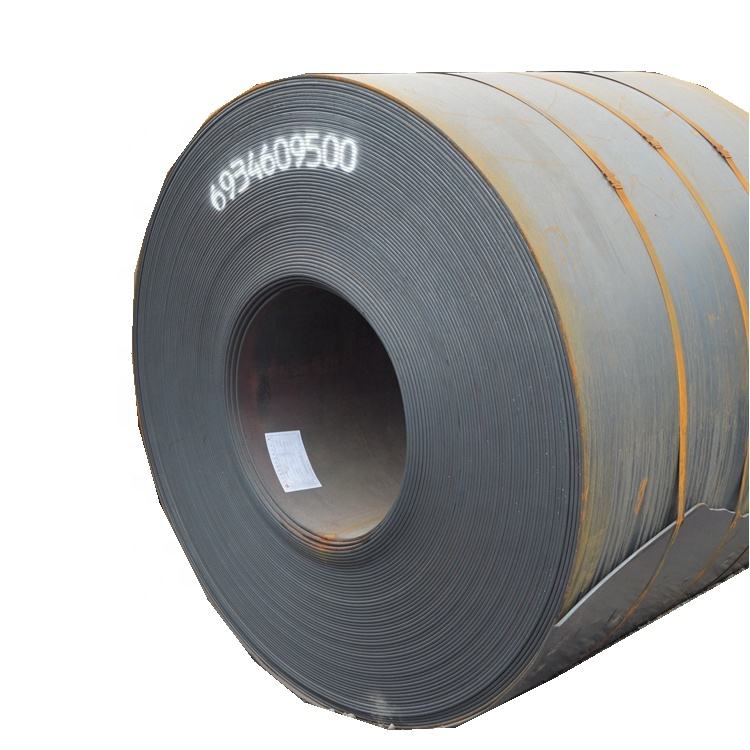

Ss400, Q235, Q345 Sphc Dub Hlau Carbon Steel Chev Hlau Hlau Hlau Hr Kub Rolled Steel Chev

Kub dov steet / coil los ntawm kev ua tiav qhov kawg kub steel sawb zeb tawm los ntawm laminar ntws txias mus rau qhov kub thiab txias, uas muaj cov winder coil, steel coil tom qab txias, raws li qhov sib txawv ntawm cov neeg siv khoom, nrog cov kab sib txawv (pas , straightening, transverse los yog longitudinal txiav, tshuaj xyuas, hnyav, ntim thiab logo, thiab lwm yam) thiab dhau los ua steel phaj, tiaj yob thiab longitudinal txiav steel sawb khoom.Vim tias cov khoom kub kub dov steel muaj lub zog siab, zoo toughness, yooj yim ua thiab zoo weldability thiab lwm yam khoom zoo heev, nws yog dav siv nyob rau hauv shipbuilding, tsheb, choj, kev tsim kho, machinery, siab nkoj thiab lwm yam kev lag luam industries.

| Qib | Qib | Chemical Composition (%) | ||||

| q215 ua | C | Mn | Si | S | P | |

| A | 0.09-0.15 Nws | 0.25-0.55 Nws | ≤0.3 | ≤ 0.05 | ≤ 0.045 | |

| B | ≤ 0.045 | |||||

| q235 ua | A | 0.14-0.22 Nws | 0.30-0.65 Nws | ≤0.3 | ≤ 0.05 | ≤ 0.045 |

| B | 0.12-0.20 Nws | 0.30-0.70 Nws | ≤ 0.045 | |||

| C | ≤ 0.18 | 0.35-0.80 Nws | - | ≤ 0.04 | ≤ 0.04 | |

| D | ≤ 0.17 | ≤ 0.035 | ≤ 0.035 | |||

| q255 ua | A | 0.18-0.28 Nws | 0.40-0.70 Nws | ≤0.3 | ≤ 0.05 | ≤ 0.045 |

| B | ≤ 0.045 | |||||

| q275 ua | 0.28-0.38 Nws | 0.50-0.80 Nws | ≤ 0.35 | ≤ 0.05 | ≤ 0.045 | |

Cov pa roj carbon steel yog ib hom hlau uas yog cov hlau thiab carbon hlau.Nws muaj cov ntsiab lus carbon ntau dua, qis melting point thiab ntau dua durability piv rau stainless hlau.

Cov pa roj carbon steel yog cov khoom siv dav siv ntau tshaj plaws thiab kev tsim kho rau kev lag luam hauv kev lag luam loj, suav nrog cov qauv hauv hiav txwv, cov chaw tsim hluav taws xob, kev thauj mus los, kev ua tshuaj lom neeg thiab roj av thiab ua kom zoo dua.

Δ Kub dov cov khoom yog annealing nyob rau hauv txias dov annealing rauv thiab tom qab pickling nyob rau hauv acid.

Δ Txhua lub zeb yob yog grinded ntawm precision sib tsoo tshuab nrog chamfering kom zoo tom qab thawj zaug ua haujlwm.

Δ Tag nrho cov ntawv yog khaws cia rau hauv lub tank sib txawv thiab cov nplooj ntawv tau qhuav ntawm lub tshuab txhuam yob ua ntej xa.

Δ Cov nplooj ntawv no rov ua dua tom qab ntawd xa mus rau lub tshuab ncaj qha rau kev ncaj thiab khaws cov kua qaub thiab xa mus rau ntim raws li qhov loj thiab zoo.

Δ Kev tshuaj xyuas yog ua tiav ntawm ntau theem.Los ntawm cov neeg ua haujlwm paub txog kev tswj kom zoo tag nrho cov txheej txheem sab hauv ntawm dov, annealing, pickling, kho cov khib nyiab thiab lwm yam.